Workplace safety regulations are the bedrock of any well-run business. They're the rules of the road that keep your employees safe and your company out of legal trouble. These guidelines, often established by organizations like the Occupational Safety and Health Administration (OSHA), spell out the non-negotiable standards for a safe workplace, covering everything from proper equipment handling to communicating hazards.

Think of them less as a rulebook and more as a blueprint for a resilient and productive operation.

Why Workplace Safety Regulations Actually Matter

It's tempting to see safety regulations as just another bureaucratic hoop to jump through. A long, complicated checklist. But in truth, they are the foundation of a healthy, efficient, and legally sound business. Just like traffic laws create order and prevent chaos on our roads, these standards build a predictable and secure environment where your team can do their best work without putting themselves at risk.

At the end of the day, these rules are about protecting your company’s most valuable asset: its people. The whole point is to systematically find and control hazards before they turn into accidents.

The Core Principles of Safety Regulations

When you strip them down, all workplace safety regulations boil down to two simple ideas: hazard identification and risk control. This proactive mindset is what separates a truly safe workplace from one that's just reacting to problems after the fact.

- Hazard Identification: This is all about actively looking for things that could cause harm. It could be something obvious, like an unmarked wet floor, or something less apparent, like a frayed electrical cord or poor lighting in a storage area.

- Risk Control: Once you've spotted a hazard, you need to control the risk. This just means putting measures in place to either eliminate the danger completely or minimize the chances of it causing an incident.

For example, noticing that your team is constantly lifting heavy boxes is the first step (hazard identification). Providing a dolly or reconfiguring the workflow to reduce the strain is the next (risk control). This simple two-step process is the engine that drives a powerful safety culture.

"Under the OSH Act’s General Duty Clause (section 5(a)(1)), employers must provide a workplace free from any recognized hazard likely to cause death or serious physical harm. For OSHA to cite an employer under the General Duty Clause, the hazard must be recognized by the employer or in the industry."

Beyond Physical Safety

Today’s safety standards also understand that a safe workplace is about more than just avoiding slips and falls. It's about protecting long-term health, too. For instance, a poorly designed workstation can lead to chronic pain and musculoskeletal disorders down the road. For a deeper dive into this, check out our guide on https://www.mount-it.com/blogs/articles/how-to-avoid-injuries-from-poor-ergonomics.

To really see how these principles work in the real world, it helps to look at specific rules like OSHA’s Electrical Safety Guidelines. These detailed requirements show exactly how clear, actionable rules lead to tangible safety improvements for everyone.

Ultimately, a strong commitment to safety does more than prevent accidents. It builds trust, boosts morale, and increases productivity by showing employees you genuinely care about their well-being. This isn't a cost—it's an investment in a resilient, people-first organization that's built to last. For a comprehensive overview of safety topics, be sure to explore our main collection of articles and guides at https://www.mount-it.com/blogs/articles.

How Modern Safety Standards Are Evolving

Workplace safety isn't a static checklist frozen in time. It's much more like a living system, constantly adapting to new technologies, different ways of working, and even unexpected global curveballs. The trusty hard hat and safety glasses are still staples, of course, but the whole landscape of risk has expanded—and modern safety standards are hustling to keep up.

The old rulebooks were written for a world of factory floors and construction sites. Today, the very idea of a "workplace" is completely different. It could be a remote employee's home office, a high-tech manufacturing facility staffed by robotic arms, or anything in between. This massive shift demands a much more flexible and sophisticated approach to keeping people safe.

Adapting to New Technologies and Work Styles

Technology is one of the biggest forces pushing safety standards forward. Take the rise of automation in manufacturing. While robots are great at eliminating dangerous manual labor, they bring their own set of hazards—think human-robot interactions, unexpected system failures, and tricky maintenance procedures. Regulations are now starting to catch up to these complex situations, making sure that progress doesn't come at the expense of safety.

At the same time, the boom in remote and hybrid work has stretched the boundaries of workplace safety regulations far beyond the traditional office. Ergonomics has become a huge concern. Employees working from kitchen tables and makeshift desks are at a high risk for musculoskeletal problems, and that responsibility now falls on the employer to provide guidance and resources for setting up a safe, ergonomically sound home office.

This isn't just theory; we're seeing these changes reflected in recent updates from key governing bodies like OSHA, ISO, and the NFPA. They've been busy rolling out revised standards that tackle modern risks head-on. These new rules put a bigger emphasis on detailed risk assessments, the use of intrinsically safe equipment, and stronger incident reporting across all kinds of industries. To get a better sense of what's coming, you can explore a deeper analysis of these recent changes and what they mean for your business.

Responding to Environmental and Health Crises

It's not just technology, either. Modern safety standards are also being reshaped by broader environmental and health trends. Climate change, for example, is introducing new and unpredictable hazards that rulemakers now have to consider.

In areas prone to wildfires, new standards have been developed to protect outdoor workers from breathing in harmful smoke. These rules often require employers to monitor air quality, provide N95 respirators, and have a plan to move work indoors when conditions get dangerous.

These climate-related dangers show how safety is no longer just about what’s happening inside the four walls of a building. An employee's well-being can be affected by air quality from hundreds of miles away—a reality that older regulations never could have predicted.

On top of that, recent global health events have permanently woven public health concerns into our safety protocols. Infection control measures, which used to be mostly for hospitals, are now standard practice in many workplaces. This includes things like:

- Enhanced sanitation and more frequent cleaning schedules.

- Improved ventilation systems to keep indoor air healthy.

- Contingency planning for any future public health emergencies.

This fusion of health surveillance and infection control marks a fundamental change in thinking. We now understand safety more holistically, recognizing that biological hazards are just as critical to manage as mechanical or chemical ones. The most forward-thinking companies are embracing this bigger picture, adapting their safety programs not just to check a compliance box, but to build real resilience against whatever challenges tomorrow might bring. These evolving workplace safety regulations are absolutely crucial for protecting teams in our changing world.

Building a Compliant and Effective Safety Program

Knowing the workplace safety regulations is the easy part. The real work begins when you have to turn that knowledge into a living, breathing program that actually keeps people safe. A top-notch safety program isn't just a binder full of rules collecting dust on a shelf; it's an active system that’s constantly hunting for and neutralizing dangers before they can cause harm.

Don't let that intimidate you. Building a solid framework boils down to four critical pillars: deep-dive risk assessments, crystal-clear safety protocols, continuous employee training, and sharp record-keeping. Get these four components working together, and you'll do more than just satisfy the regulators—you'll build a genuine culture of safety.

The Foundation of Your Program: Risk Assessments

Every great safety program starts with a simple question: "What could go wrong here?" A risk assessment is your official process for answering that question. It means walking through your entire workplace to spot potential hazards, whether it's a simple trip hazard or the long-term ergonomic strain from a poorly set up desk.

Think of yourself as a detective inspecting a scene before a crime happens. You're searching for clues and weak spots. Once you spot a hazard, the next move is to figure out the actual risk—how likely is it to hurt someone? A puddle of water in a busy lobby is a much higher immediate risk than a wobbly shelf in a storage closet no one ever enters. This helps you prioritize what to fix first.

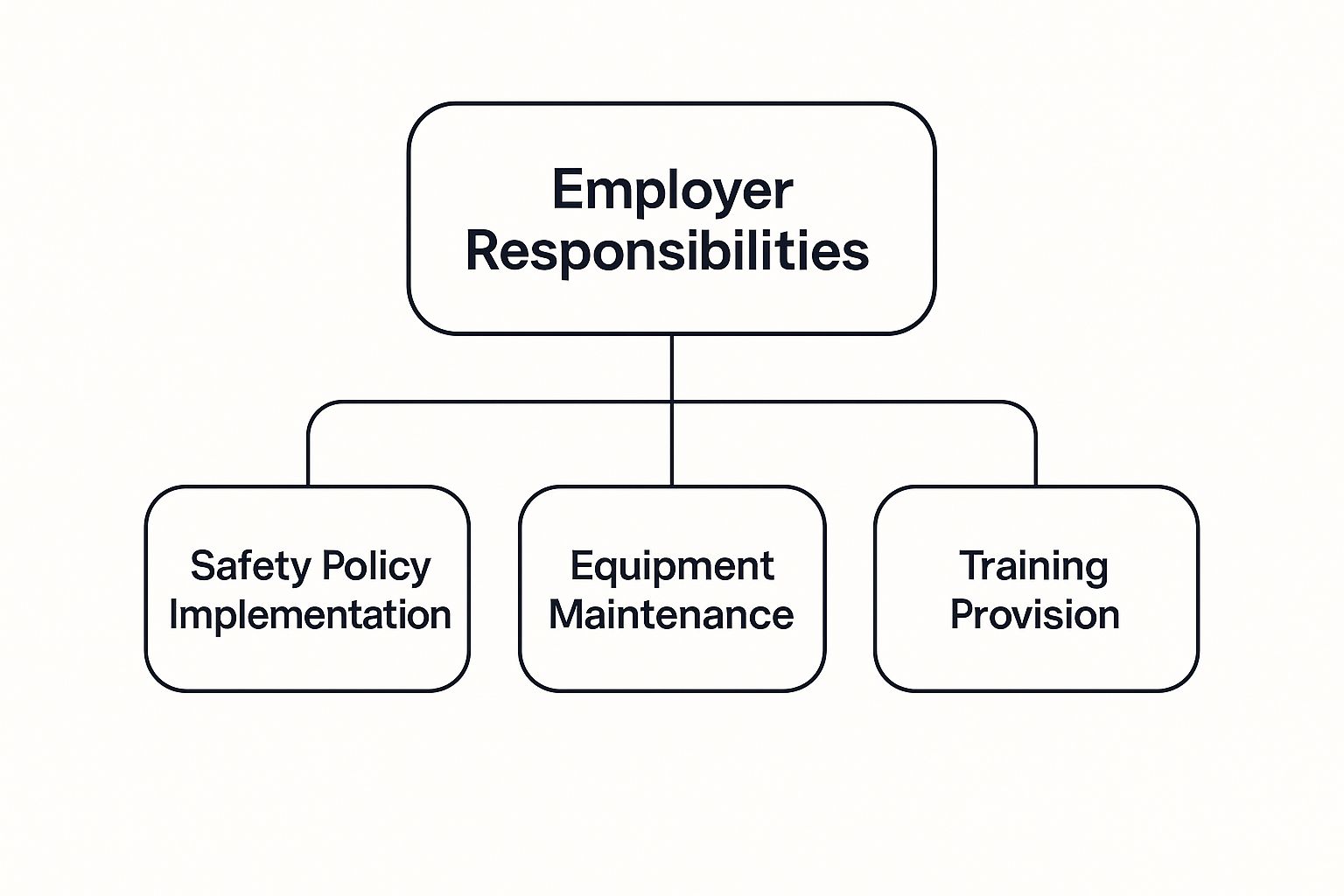

As you can see, things like providing training and maintaining equipment are direct results of having a solid safety policy—and it all starts with that initial risk assessment.

Creating Clear and Actionable Safety Protocols

Once you’ve identified the risks, you need to write down the rules for controlling them. These are your safety protocols—the specific, step-by-step instructions your team must follow to do their jobs safely. Vague advice like "be careful" just doesn't cut it. Your protocols need to be incredibly specific.

For example, instead of a general rule about lifting, a strong protocol would spell out:

- The maximum lifting weight for one person.

- When to use mandatory team lifts or equipment for heavier items.

- Exactly how to perform proper lifting techniques to protect the back.

These instructions should be easy for everyone to find and written in plain language. The goal is to make the safe way the most obvious and easiest way to work. In certain industries, these rules are extremely detailed. For instance, anyone in transportation knows that understanding specific qualifications like the Commercial Driver's License (CDL) requirements is a non-negotiable part of the safety playbook.

Making Employee Training an Ongoing Conversation

Your safety plan is worthless if your team doesn't know it, understand it, and believe in it. That's where training comes in, but it has to be more than just a boring video during orientation. Real, effective training is a continuous conversation that keeps safe habits top-of-mind and adapts as new challenges pop up.

The most impactful training programs combine initial instruction with regular refreshers, hands-on demonstrations, and daily safety reminders. This transforms safety from an abstract concept into a practical, daily habit.

Training needs to be interactive. Run emergency drills. Have teams do a "hazard hunt" in their own workspace. The point is to give employees ownership and empower them to be active partners in keeping themselves and their colleagues safe.

Transforming Record-Keeping into a Predictive Tool

The final pillar, record-keeping, is what holds everything together and fuels improvement. This isn't just about checking a box for compliance; it's about gathering intelligence that can stop incidents from happening in the first place.

Your records are a treasure trove of data that, when analyzed, can reveal hidden patterns. A good starting point is our table below, which outlines the essential components of a robust workplace safety program.

| Pillar | Core Purpose | Key Actions |

|---|---|---|

| Management Leadership & Employee Involvement | To establish safety as a core company value from the top down and empower all employees. | - Management visibly commits to safety. - Employees participate in policy creation. - Establish a clear system for reporting issues without fear. |

| Worksite Analysis | To proactively identify and understand existing and potential hazards. | - Conduct regular inspections and risk assessments. - Investigate all incidents and "near misses." - Analyze injury and illness data to spot trends. |

| Hazard Prevention & Control | To eliminate or reduce safety and health hazards. | - Implement engineering controls (e.g., machine guards). - Establish safe work procedures and protocols. - Provide and ensure use of Personal Protective Equipment (PPE). |

| Safety & Health Training | To ensure all employees and managers understand their roles and responsibilities in the safety program. | - Conduct initial orientation for all new hires. - Provide job-specific hazard training. - Hold regular refresher courses and emergency drills. |

By tracking things like training completion, inspection logs, and incident reports, you can start connecting the dots. Are most back injuries happening in one department? Maybe it’s time to revisit their ergonomic setups. Learning more about the benefits of standing desks could point you toward a practical solution. This data-first approach turns record-keeping from a boring chore into a powerful tool for predicting and preventing the next accident.

The Real-World Impact of Strong Safety Rules

It’s easy to see safety regulations as just another box to check, another layer of red tape. But their real impact isn't measured in paperwork—it’s measured in the number of people who get to go home to their families at the end of the day, safe and sound.

This isn't some abstract idea. It's a story told through decades of data, showing a clear, direct line between putting strong rules in place and saving lives.

These regulations are the guardrails that keep catastrophic failures from happening. Before landmark safety laws came into play, workplaces were incredibly dangerous places, and preventable accidents were tragically common. The shift to clear, enforceable standards turned safety from an afterthought into a non-negotiable part of doing business.

The data makes this transformation crystal clear. The numbers don't just show progress; they represent countless individuals who were kept from harm because we got serious about finding and fixing hazards.

A Legacy of Saved Lives

Take the Occupational Safety and Health (OSH) Act in the United States. Its impact has been nothing short of monumental. Since it was enacted, it’s estimated that this single piece of legislation has saved over 712,000 workers' lives in the last 54 years.

But the job is far from finished. Workplace hazards are still a major global problem. In a recent year, around 140,000 workers died annually from work-related causes worldwide. That figure breaks down to roughly 5,283 deaths from traumatic injuries and a staggering 135,000 deaths from occupational diseases. For a deeper dive into these numbers, you can read the full report on the state of safety and health for workers.

What this tells us is that while we've made incredible strides, we can't let our guard down. Every single incident is a reminder that our commitment to safety has to be unwavering.

The Ripple Effect of a Safer Workplace

Beyond the life-or-death stats, strong safety rules create a positive ripple effect that touches every corner of a company. When people feel safe at work, they’re more focused, more productive, and more engaged. A well-run safety program builds trust between employees and management, creating a culture where everyone looks out for each other.

This proactive approach pays off in a lot of ways:

- Fewer Incidents: Less accidents means less downtime, lower workers' compensation claims, and more stable insurance costs.

- Better Morale: When a company shows it cares about its people's well-being, morale goes up and people are more likely to stick around.

- Stronger Reputation: Businesses known for their stellar safety records attract the best talent and become the preferred partners for clients.

Think of it like regular maintenance on your car. You get oil changes and check your brakes (the safety regulations) to prevent a catastrophic engine failure or a serious accident down the road. It’s a consistent, proactive investment that keeps things running smoothly and averts disaster.

Safety in the Modern Workspace

These principles aren't just for construction sites or factory floors; they extend right into the modern office. The dangers might seem less immediate, but poor ergonomics can lead to chronic, debilitating injuries over time. Musculoskeletal disorders from a bad desk setup are a real threat that a solid safety program needs to address.

The best safety plans are holistic. They account for both the sudden, obvious dangers and the slow-burn health risks. That means creating workspaces that support physical well-being and prevent those creeping injuries that can be just as damaging as a sudden accident.

Making sure your team has the right gear and the right knowledge is key. For some practical tips on this front, check out our guide on creating a proper https://www.mount-it.com/blogs/articles/ergonomic-desk-setup.

At the end of the day, the data and the real-world results all point to one simple truth: investing in and following workplace safety rules is one of the smartest, most important decisions a company can make. It protects lives, it strengthens the business, and it lays the groundwork for lasting success.

Learning From Industry-Specific Safety Wins

General safety guidelines are a great start, but the real magic happens when you zoom in. The most powerful safety improvements almost always come from programs tailored to a specific industry's unique risks.

When you look at high-risk fields like construction or electrical work, the proof is right there in the numbers. Targeted safety campaigns deliver real, measurable results. These success stories offer a powerful blueprint for any company looking to protect its people, no matter the industry.

It’s about focusing on the specific dangers workers face every single day. This allows companies and regulators to create strategies that get right to the root cause of accidents. Think of it like a mechanic using a specialized wrench instead of a generic adjustable one—the specialized tool gets the job done better, faster, and much more safely. This focused approach is what turns abstract workplace safety regulations into life-saving actions.

How Targeted Campaigns Drive Down Risk

A perfect example comes from the world of powered access equipment—think cherry pickers and scissor lifts. One of the biggest dangers for operators is working near overhead power lines, which carries a severe risk of electrocution. In response, industry groups didn't just issue a vague warning; they launched focused campaigns to hammer home this specific hazard.

These initiatives went way beyond a simple memo. They included:

- Simple, Clear Communication: Creating easy-to-understand visual guides showing safe distances from power lines.

- Realistic Training: Building training modules that simulated real-world scenarios involving overhead electrical dangers.

- Smarter Equipment: Pushing for the use of insulated equipment and proximity alarms that shriek a warning when an operator gets too close to a live wire.

This all-hands-on-deck effort led to massive improvements. The International Powered Access Federation's (IPAF) Global Safety Report showed a stunning 33% decrease in fatalities involving Mobile Elevating Work Platforms (MEWPs) in just one year. Even more telling, the report recorded a 31% decrease in electrocutions and electric shocks. It’s clear proof that homing in on a specific problem works.

Lessons From Construction and Beyond

The construction industry gives us another fantastic case study. For what felt like an eternity, falls from height were a leading cause of death on job sites. So, regulators and industry leaders got together and created the "National Safety Stand-Down to Prevent Falls in Construction," an annual event where all work stops for a dedicated conversation about fall prevention.

This isn't just another boring meeting. It’s a hands-on commitment. During the stand-down, employers talk directly with their teams about the specific fall hazards on their current site, they inspect their gear, and they review rescue plans. This simple but powerful intervention has been directly credited with raising awareness and dramatically reducing fall-related injuries and deaths across the country.

The core lesson here is simple: the most effective safety measures are never one-size-fits-all. They are born from a deep, practical understanding of the specific risks that come with a particular job.

This principle works everywhere, even in a seemingly safe office environment. The risks might look different, but the strategy is identical. An office-based company can launch targeted ergonomic initiatives to prevent musculoskeletal disorders—which are basically the "falls from height" of the corporate world. For a step-by-step guide, check out our office ergonomics checklist for a healthier workspace.

By identifying and tackling the unique dangers of desk work, you can achieve the same kinds of safety wins, proving that a focused, tailored approach to safety always pays off.

Common Questions About Workplace Safety Regulations

Stepping into the world of workplace safety regulations can feel a bit like trying to solve a puzzle with a few pieces missing. To help you see the full picture, we've gathered some of the most common questions we hear from business owners and managers. Our goal is to give you simple, direct answers you can put to work right away.

What Are the First Steps for a Small Business to Comply?

For a small business, just the thought of compliance can feel huge, but you don't have to do it all at once. It's best to start with a few foundational steps.

First things first, figure out which specific regulations (like those from OSHA) actually apply to your industry. Not every rule is for every business, so knowing your specific obligations is the perfect starting point.

Once you know the rules of the road, do a thorough risk assessment of your entire facility. This isn't just a casual glance—it means walking through your space and actively looking for potential hazards. Think of anything from a frayed electrical cord to a poorly lit hallway.

With your findings in hand, create a straightforward, written safety plan. This doesn't need to be a massive, complicated document. It just needs to outline your procedures for handling the hazards you've identified. And finally, the most critical step: train every single employee on this plan so they understand the risks and know exactly how to stay safe.

How Often Should We Conduct Safety Training?

The "right" frequency for safety training really boils down to the level of risk in your day-to-day operations. As a solid baseline, all new hires should get comprehensive safety training as part of their onboarding process. From there, holding an annual refresher course for the whole team is a widely accepted best practice.

But that baseline isn't a one-size-fits-all solution. If your team handles any high-hazard tasks, you'll need more frequent, specialized training sessions. You should also schedule new training anytime you introduce new equipment, chemicals, or work processes that change the safety landscape for your employees.

Here's a piece of the puzzle you can't afford to lose: documentation. Always keep detailed records of every training session—who attended, what topics were covered, and the date. This isn't just about being organized; it's an essential part of maintaining compliance and showing your commitment to a strong safety culture.

What Is the Difference Between a Hazard and a Risk?

It's easy to use "hazard" and "risk" interchangeably, but knowing the difference is fundamental to managing workplace safety effectively. The distinction is simple but powerful.

A hazard is anything with the potential to cause harm. Think of it as the source of the danger itself.

- A slippery, wet floor.

- A chemical stored in an unlabeled container.

- A power tool with a missing safety guard.

A risk, on the other hand, is the likelihood that the hazard will actually cause harm, combined with how severe that harm might be. That wet floor (the hazard) poses a much higher risk in a busy main entrance than it does in a locked storeroom no one ever enters. Smart safety management is all about identifying those hazards, then evaluating the risks to figure out what needs to be fixed first.

Are We Responsible for the Safety of Our Remote Workers?

Yes, absolutely. An employer's fundamental duty of care doesn't stop at the office door; it extends to employees working from home. While you can't control their home environment, you are responsible for giving them the guidance and resources they need to create a safe home workspace.

Most often, this means offering clear advice on ergonomic setups to prevent strains and long-term issues. Guidance on proper monitor height, chair support, and keyboard placement is crucial. A great starting point is our detailed guide on how to reduce back pain from sitting at a desk, which is packed with practical tips for any workspace.

Beyond the physical setup, it's also important to think about psychological safety. This includes promoting a healthy work-life balance with clear communication, setting manageable workloads to prevent burnout, and encouraging regular breaks. Giving your remote team a simple home office safety checklist can be a fantastic tool to empower them to build a safe and productive environment for themselves.

At Mount-It, we believe that a safe and ergonomic workspace is the foundation of productivity and well-being. From sit-stand desks to monitor mounts, our solutions are designed to help you build a compliant and comfortable environment for your team. Explore our full collection of articles and guides at https://www.mount-it.com/blogs/articles, or browse our product solutions at https://www.mount-it.com.